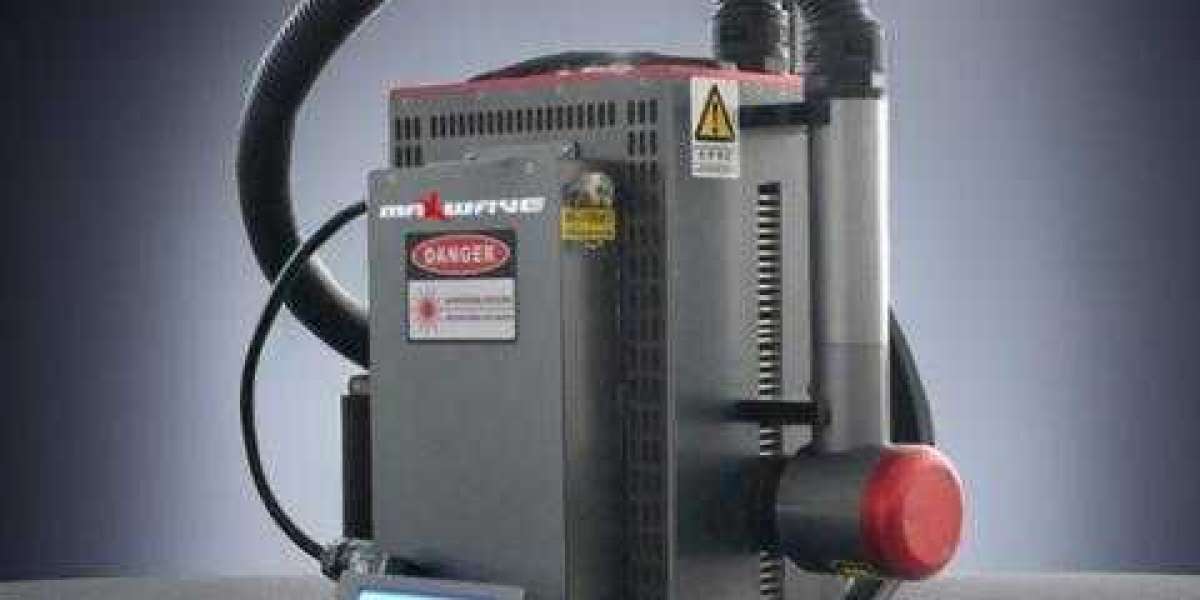

Are you tired of traditional cleaning methods that are time-consuming, messy, and sometimes harmful to the environment? It's time to embrace the future of cleaning with laser cleaning machines. These innovative devices utilize cutting-edge technology to remove contaminants, rust, paint, and more from various surfaces efficiently and effectively.

How Laser Cleaning Machines Work

Laser cleaning machines operate by using high-intensity laser beams to vaporize unwanted substances from surfaces. Unlike traditional methods such as sandblasting or chemical cleaning, laser cleaning is non-contact, meaning there is no abrasion or damage to the surface being cleaned. This makes it ideal for delicate materials like historical artifacts, automotive parts, and delicate machinery.

Benefits of Laser Cleaning

Environmentally Friendly: Say goodbye to harmful chemicals and abrasive materials. Laser cleaning is an eco-friendly solution that produces no waste and eliminates the need for hazardous cleaning agents.

Precision Cleaning: Laser cleaning allows for precise targeting of contaminants, ensuring thorough cleaning without damaging the underlying surface. This precision is particularly beneficial in industries where accuracy is paramount.

Time and Cost-Efficient: Traditional cleaning methods often require extensive preparation, cleanup, and downtime. Laser cleaning machines streamline the process, reducing labor costs and increasing productivity.

Versatility: From removing rust and paint to degreasing and surface preparation, laser cleaning machines can tackle a wide range of cleaning applications across various industries.

Safety: Unlike abrasive methods that can produce dust and debris, laser cleaning generates minimal secondary waste, creating a safer work environment for operators.

Applications of Laser Cleaning

The versatility of laser cleaning machines makes them invaluable across numerous industries:

Automotive: Remove rust and paint from car bodies, engine parts, and wheels with precision and efficiency.

Aerospace: Prepare surfaces for bonding and welding while maintaining strict cleanliness standards.

Manufacturing: Clean molds, tools, and equipment without the need for disassembly, reducing downtime and increasing operational efficiency.

Historical Restoration: Safely clean delicate artifacts and structures without causing damage or degradation.

Electronics: Remove contaminants from circuit boards, connectors, and other electronic components with precision.

Choosing the Right Laser Cleaning Machine

When selecting a laser cleaning machine for your specific needs, consider factors such as power output, beam quality, scanning capability, and portability. Whether you require a compact handheld device for onsite cleaning or a high-powered system for industrial applications, there's a laser cleaning solution to suit your requirements.

Invest in the Future of Cleaning

Upgrade your cleaning process with laser cleaning machines and experience the difference firsthand. Say goodbye to outdated cleaning methods and hello to a safer, more efficient, and environmentally friendly solution. Join the countless industries already benefiting from this revolutionary technology and take your cleaning operations to the next level.

Conclusion

Laser cleaning machines represent a paradigm shift in the way we approach cleaning and surface preparation. With their unparalleled precision, efficiency, and versatility, they offer a superior alternative to traditional cleaning methods. Invest in the future of cleaning today and revolutionize your cleaning process with laser technology.