Industrial cleaning is a critical aspect of maintaining optimal performance and efficiency in manufacturing and production facilities. Traditional cleaning methods often involve time-consuming processes that may not deliver the desired results. However, with the advent of industrial laser cleaner technology, a new era of precision cleaning has emerged. In this comprehensive guide, we'll explore the capabilities of industrial laser cleaner technology, its advantages over traditional methods, and how it's revolutionizing industrial cleaning practices.

Unveiling Industrial Laser Cleaner Technology:

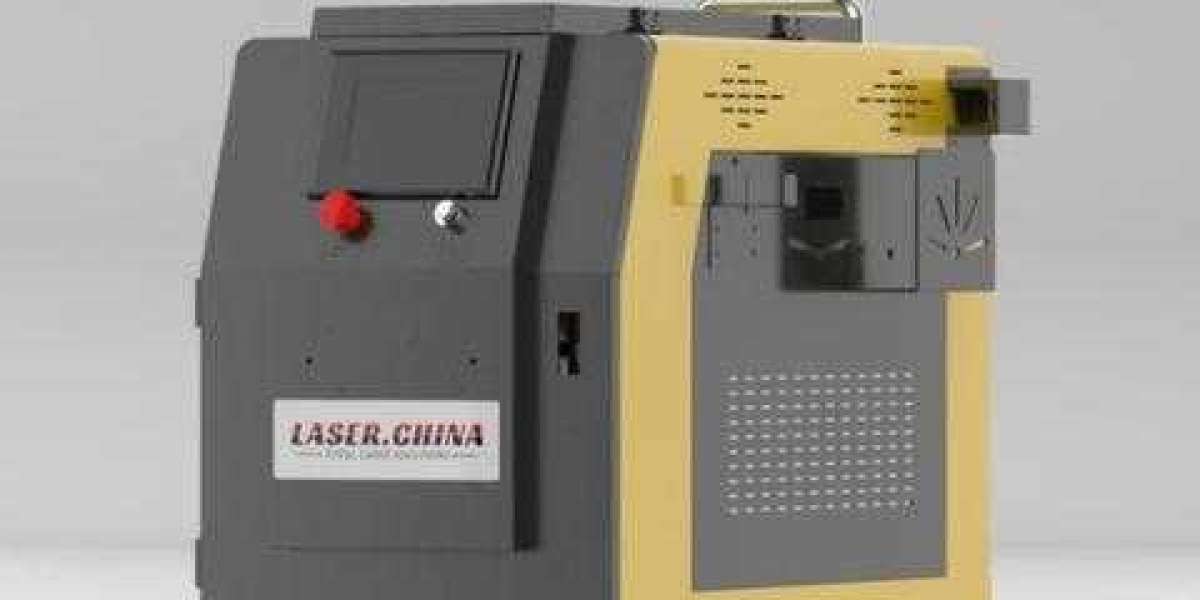

Industrial laser cleaner technology harnesses the power of high-intensity laser beams to remove contaminants such as oil, grease, paint, rust, and oxide layers from surfaces with unparalleled precision and efficiency. Unlike abrasive methods or chemical treatments, industrial laser cleaning is non-contact and non-abrasive, preserving the integrity of the underlying material while achieving thorough cleaning results. These advanced machines are specifically designed to meet the rigorous cleaning demands of industrial settings.

Advantages of Industrial Laser Cleaner Technology:

Precision Cleaning: Industrial laser cleaner technology offers precise removal of contaminants from surfaces without causing damage to the substrate material. The focused laser beam selectively targets contaminants, leaving the base material unaffected and free from damage.

Efficiency and Speed: Laser cleaning is a rapid and efficient process, capable of removing contaminants from surfaces in a fraction of the time required by traditional methods. Industrial laser cleaner machines enable users to complete cleaning tasks quickly and efficiently, reducing downtime and increasing productivity.

Versatility in Applications: Industrial laser cleaner technology is suitable for a wide range of materials, including metals, plastics, ceramics, and composites. It can be used in various industrial sectors, including automotive, aerospace, electronics, manufacturing, and more.

Environmentally Friendly: Industrial laser cleaner technology is environmentally friendly, producing no hazardous waste or harmful emissions. It eliminates the need for chemicals or abrasive materials, making it a clean and sustainable solution for industrial cleaning.

Applications of Industrial Laser Cleaner Technology:

Manufacturing and Production Facilities: Industrial laser cleaner machines are used in manufacturing plants for cleaning machinery, equipment, and industrial surfaces. They remove contaminants such as oil, grease, paint, and rust, ensuring optimal performance and product quality.

Automotive Manufacturing: Automotive production facilities utilize industrial laser cleaner technology for cleaning engine components, chassis parts, and body panels. They remove contaminants such as oil, grease, and rust, ensuring the quality and reliability of automotive products.

Aerospace and Aviation: Aerospace manufacturers employ industrial laser cleaner machines for cleaning aircraft components, such as turbine blades, engine housings, and structural elements. They remove contaminants without damaging sensitive aerospace materials, ensuring safety and reliability in flight.

Electronics Manufacturing: Industrial laser cleaner technology is used in electronics manufacturing for cleaning circuit boards, electronic components, and semiconductor wafers. They remove contaminants such as flux residues and oxide layers, ensuring the reliability and functionality of electronic devices.

Choosing the Right Industrial Laser Cleaner:

When selecting an industrial laser cleaner, consider factors such as power output, beam quality, scanning capabilities, and mobility. Additionally, assess your specific cleaning needs and budget constraints to choose a machine that offers the best value for your investment.

Conclusion:

Industrial laser cleaner technology offers precision cleaning power with unparalleled efficiency and versatility. Whether in manufacturing, automotive production, aerospace, electronics manufacturing, or other industrial sectors, industrial laser cleaners provide efficient, eco-friendly, and precise cleaning solutions. Embrace the precision and efficiency of industrial laser cleaning technology and elevate your industrial cleaning practices to new heights.