In the quest for cleanliness and efficiency, traditional cleaning methods often fall short, leaving behind residues, contaminants, and surface damage. However, with the advent of laser cleaner machines, a new era of cleaning has dawned. Let's delve into the world of laser cleaner machines and uncover how they're revolutionizing the cleaning industry.

Unveiling the Power of Laser Cleaner Machines

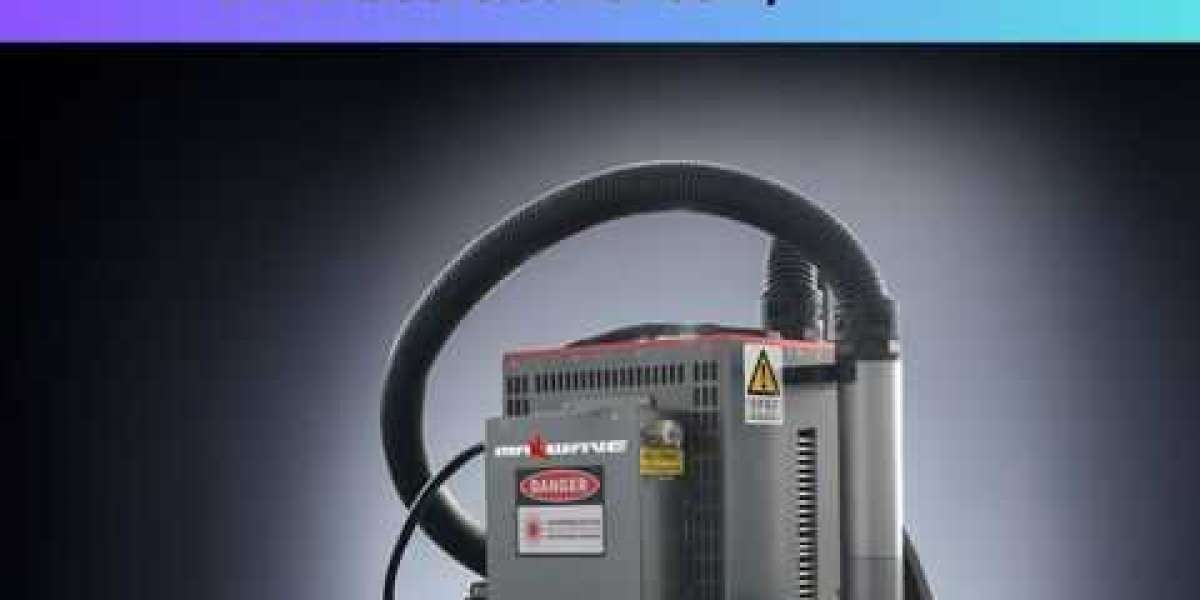

Laser cleaner machines harness the power of focused laser beams to remove contaminants, coatings, and residues from surfaces with unparalleled precision and efficiency. Here's why they're making waves in various industries:

- Precision Cleaning: Laser cleaner machines deliver precise and targeted cleaning, effectively removing contaminants from intricate geometries and delicate surfaces without causing damage.

- Non-contact Operation: Unlike traditional cleaning methods that rely on abrasive materials or harsh chemicals, laser cleaner machines operate without touching the surface, reducing the risk of surface damage and minimizing the need for secondary cleaning processes.

- Versatility: From rust and paint removal to degreasing and surface preparation, laser cleaner machines can tackle a wide range of cleaning applications across metals, plastics, composites, and more.

- Environmentally Friendly: Laser cleaner machines eliminate the need for chemicals and abrasive materials, making them an eco-friendly cleaning solution that reduces waste and environmental impact.

- Efficiency: With rapid cleaning speeds and minimal setup requirements, laser cleaner machines offer increased productivity and shorter cleaning cycles, ultimately saving time and labor costs.

Applications of Laser Cleaner Machines

The versatility and precision of laser cleaner machines make them invaluable across a multitude of industries:

- Manufacturing: In manufacturing facilities, laser cleaner machines are used for surface preparation, weld cleaning, and removal of contaminants from metal, plastic, and composite materials.

- Automotive: Laser cleaner machines play a vital role in automotive manufacturing and repair, facilitating the removal of rust, paint, and adhesive residues from car bodies, engine components, and other automotive parts.

- Aerospace: In the aerospace industry, where cleanliness is critical for safety and performance, laser cleaner machines are utilized for precision cleaning of aircraft components, turbine blades, and critical surfaces without damaging sensitive materials.

- Historical Restoration: Laser cleaner machines are employed in the restoration of historical artifacts, monuments, and architectural structures, allowing for gentle removal of dirt, pollutants, and graffiti while preserving the integrity of the underlying materials.

- Electronics: In electronics manufacturing, laser cleaner machines are used for precision cleaning of circuit boards, connectors, and semiconductor components, ensuring optimal performance and reliability of electronic devices.

Investing in Innovation

As industries continue to prioritize efficiency, safety, and sustainability, investing in innovative cleaning technologies like laser cleaner machines becomes essential. Whether you're a small-scale manufacturer or a large industrial enterprise, laser cleaner machines offer a versatile and cost-effective solution to optimize your cleaning processes and improve overall productivity.

Experience the power of precision cleaning with laser cleaner machines and elevate your cleaning game to new heights.