The Emergence of 3D Printing Services in India

In recent years, India has seen a significant rise in 3D printing services, driven by the need for faster, more flexible, and cost-effective manufacturing solutions. Companies across the country are leveraging this technology to streamline their production processes and reduce time-to-market for new products. From automotive to healthcare, 3D printing is finding applications in a myriad of sectors, enabling businesses to innovate and thrive in a competitive market.

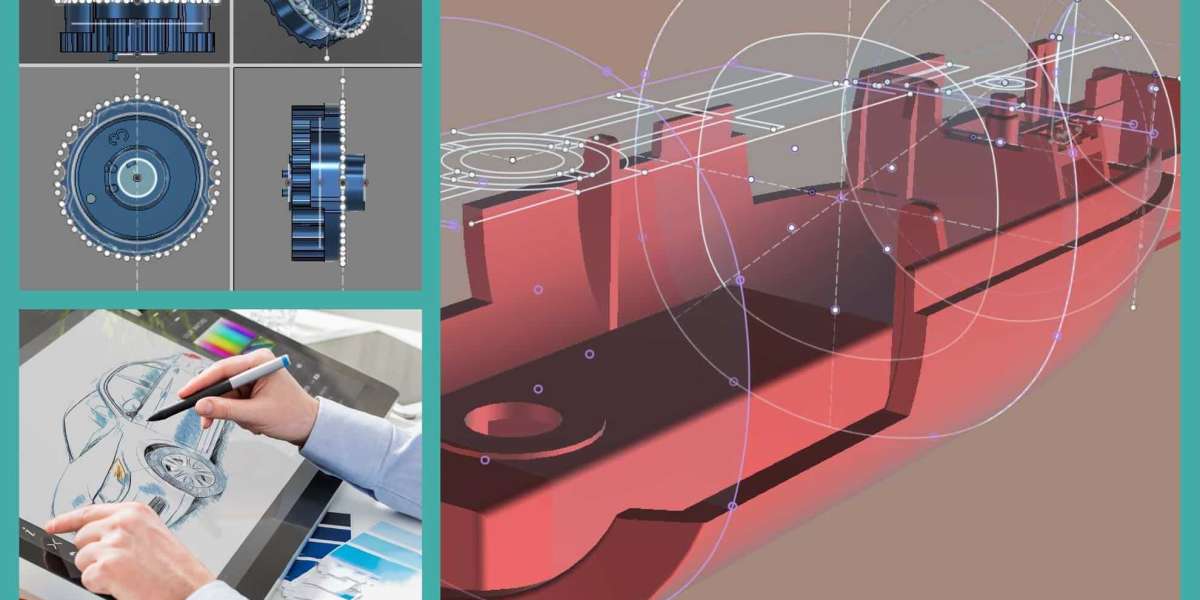

3D printing service in India is not just about creating objects; it's a comprehensive solution that encompasses various aspects of manufacturing, including prototyping, design, and final product creation. This holistic approach allows for a seamless integration of design and manufacturing processes, leading to improved product quality and performance.

Revolutionizing 3D Product Design

The advent of 3D printing has revolutionized product design, offering unparalleled flexibility and creativity. Designers now have the liberty to experiment with complex geometries and structures that were once deemed impossible to manufacture using traditional methods. This has opened up new avenues for innovation, allowing for the creation of bespoke and intricate designs tailored to specific customer needs.

In India, 3D product design is gaining traction, with companies and startups increasingly investing in this technology to enhance their product offerings. The ability to quickly prototype and test designs without the need for expensive tooling and machinery has significantly reduced development costs and increased efficiency.

The Impact on Manufacturing Efficiency and Sustainability

3D printing is not only about enhancing design and production capabilities; it also plays a crucial role in improving manufacturing efficiency and sustainability. By enabling on-demand production, 3D printing reduces the need for inventory, minimizes waste, and lowers the carbon footprint associated with manufacturing.

In India, where there is a growing emphasis on sustainable and eco-friendly manufacturing practices, 3D printing offers a promising solution. It allows companies to produce closer to the point of consumption, reducing transportation costs and emissions, and supporting the local economy.

The Future of 3D Printing in India

The future of 3D printing in India looks promising, with the market set to expand as technology advances and becomes more accessible. The government's support for digital manufacturing initiatives and the increasing investment in research and development are likely to fuel further growth in this sector.

Education and skill development are also critical to the widespread adoption of 3D printing technology. As more educational institutions and training centers offer courses in 3D printing and design, India is poised to build a skilled workforce capable of driving innovation in manufacturing.

Conclusion

3D printing is revolutionizing manufacturing in India, offering unprecedented opportunities for innovation, efficiency, and sustainability. As 3D printing service in India continues to evolve, it is set to play a pivotal role in shaping the future of the manufacturing industry, making it more agile, innovative, and environmentally responsible. The journey of 3D printing in India is just beginning, and it promises to lead the manufacturing sector towards a brighter and more dynamic future.