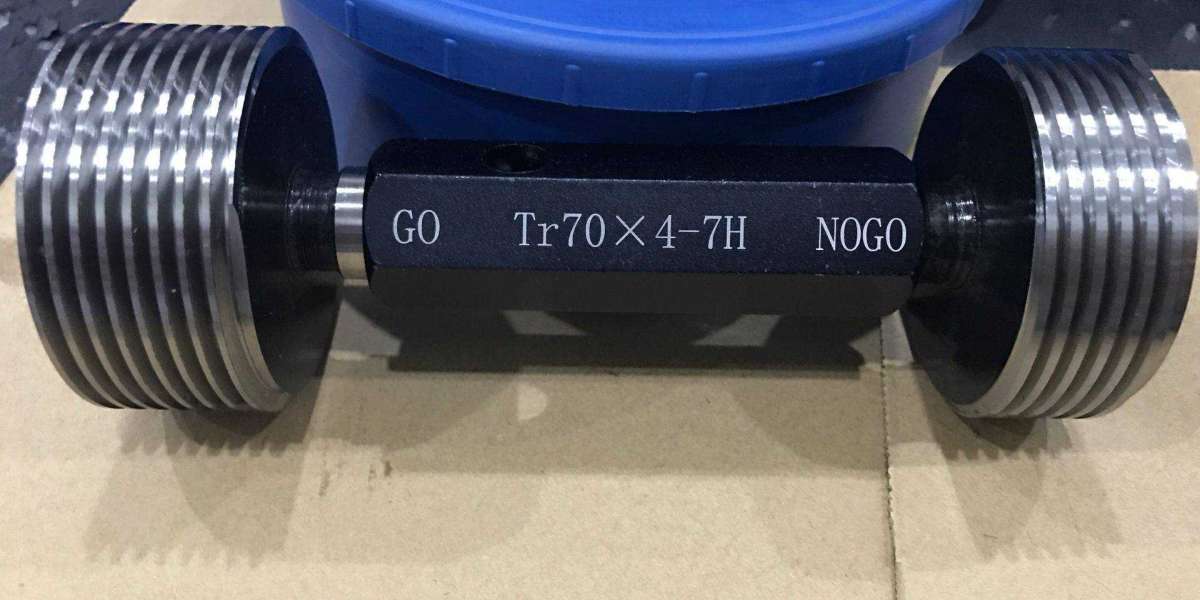

Strategically constructing your sourcing calendar for thread plug gauges holds the potential for substantial cost savings within your business operations. Thread plug gauges, these precise tools entrusted with upholding the integrity of internal threads in nuts, holes, and pipes, play an irreplaceable role across industries, spanning manufacturing to construction. Nevertheless, the significance of meticulously planning the timing and method of procuring these essential instruments is frequently undervalued.

Inadequate planning can lead to a series of costly issues, including production delays, increased expenses, and compromises in product quality. Delays in production can be particularly damaging, as they disrupt timelines and lead to missed deadlines, potentially affecting customer satisfaction and contractual obligations. Rush orders and last-minute purchases, driven by unplanned demand for thread plug gauges, often come at premium prices, eroding profitability.

Moreover, the rush to acquire these tools can lead to unintended compromises in quality. Businesses may opt for lower-quality or non-standard thread plug gauges in their haste, jeopardizing the precision and reliability of threaded connections. This, in turn, can result in costly rework, product defects, and even potential liabilities in industries where safety standards are paramount.

Strategic planning of your sourcing calendar offers a range of benefits, primarily centered around cost reduction and operational efficiency. It allows for optimized inventory management, ensuring you have an adequate supply of thread plug gauges to meet demand without overstocking, tying up capital, or taking up excessive storage space.

Moreover, a well-thought-out sourcing calendar enables you to leverage bulk purchasing opportunities, negotiate better prices, and minimize the need for expensive last-minute rush orders. This translates to significant cost savings in the long run, boosting your bottom line. Additionally, it streamlines your procurement processes, reducing administrative overhead and allowing your team to focus on more value-added activities.

Quality assurance is another vital aspect of strategic planning. With a well-structured sourcing calendar, you have the time to source high-quality, certified thread plug gauges and ACME thread gauges that meet industry standards. This proactive approach reduces the risk of costly defects, recalls, or product failures, safeguarding your reputation and customer trust.

Furthermore, planning your sourcing calendar helps you identify potential bottlenecks and supply chain risks in advance, enabling you to implement contingency plans and minimize disruptions to your operations. By considering historical data, lead times, seasonal variations, supplier relationships, and contingency planning, you can craft a sourcing calendar that not only saves costs but also enhances efficiency and minimizes risks.

Planning your sourcing calendar for thread plug gauges is not just a logistical task; it is a strategic investment in cost savings, operational efficiency, and product quality. In industries where precision and reliability are paramount, a well-executed sourcing calendar can be the linchpin of your project's success and your company's financial health. So, take the time to strategize when and how you source thread plug gauges—it is a wise investment that pays off in the long run. Do not wait until the last minute to start your sourcing process.