In today's rapidly advancing technological landscape, traditional cleaning methods are being replaced by more efficient and eco-friendly alternatives. One such innovation is the laser cleaning machine, which utilizes the power of laser beams to remove contaminants from various surfaces without the need for harsh chemicals or manual labor. In this guide, we'll delve into the workings oflaser cleaning machine, their applications, benefits, and how they can revolutionize your cleaning processes.

How laser cleaning machine Work: Laser cleaning machines operate by directing a high-intensity laser beam onto the surface to be cleaned. When the laser beam interacts with the contaminants, such as rust, paint, or oil, it vaporizes or ablates them, leaving behind a clean surface. This process is highly precise and controlled, ensuring minimal damage to the underlying material.

Key Components and Features:

- Laser Source: The heart of the laser cleaning machine is the laser source, which emits the high-energy laser beam. Different types of lasers, such as fiber lasers or pulsed lasers, may be used depending on the specific cleaning requirements.

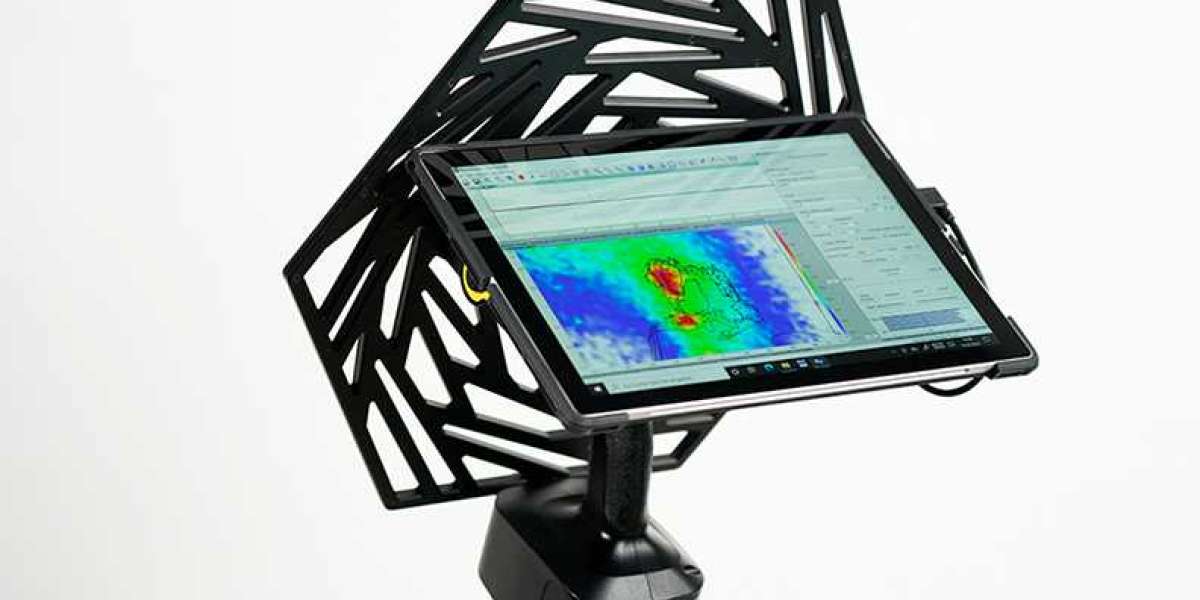

- Optics System: The optics system focuses and directs the laser beam onto the target surface with pinpoint accuracy.

- Control System: Advanced control systems allow users to adjust parameters such as laser intensity, scanning speed, and focal distance to achieve optimal cleaning results.

- Safety Features:laser cleaning machine are equipped with safety measures to protect operators from exposure to laser radiation, including interlocks, safety curtains, and emission monitoring systems.

Applications oflaser cleaning machine:laser cleaning machine find diverse applications across various industries, including:

- Manufacturing: Removing coatings, residues, and contaminants from metal, plastic, and composite components.

- Restoration: Restoring historical artifacts, monuments, and delicate surfaces without causing damage.

- Automotive: Preparing surfaces for welding, painting, or bonding in automotive manufacturing and repair.

- Aerospace: Cleaning engine components, turbine blades, and aircraft structures to maintain performance and safety standards.

- Conservation: Preserving artworks, sculptures, and cultural heritage sites by gently removing accumulated dirt and pollutants.

Benefits of laser cleaning machine

- Environmentally Friendly: Laser cleaning eliminates the need for chemical solvents, reducing hazardous waste and environmental pollution.

- Cost-effective: By eliminating the use of consumables and minimizing manual labor,laser cleaning machine offer long-term cost savings.

- Non-contact Cleaning: Laser cleaning is a non-abrasive process that preserves the integrity of delicate surfaces and minimizes the risk of damage.

- Versatility: laser cleaning machinecan be adapted to clean a wide range of materials and surface geometries, making them highly versatile tools.

- Efficiency: With rapid cleaning speeds and precise controllaser cleaning machinesignificantly reduce downtime and increase productivity.

Conclusion: laser cleaning machine represent a cutting-edge solution for efficient, eco-friendly, and precise surface cleaning across various industries. By understanding their working principles, applications, and benefits, you can leverage this technology to revolutionize your cleaning processes and achieve superior results with minimal environmental impact.