In the realm of industrial machinery, grinder segments play a pivotal role in shaping precision and efficiency. These small but mighty components are the unsung heroes behind the flawless finish and accuracy achieved in various grinding applications.

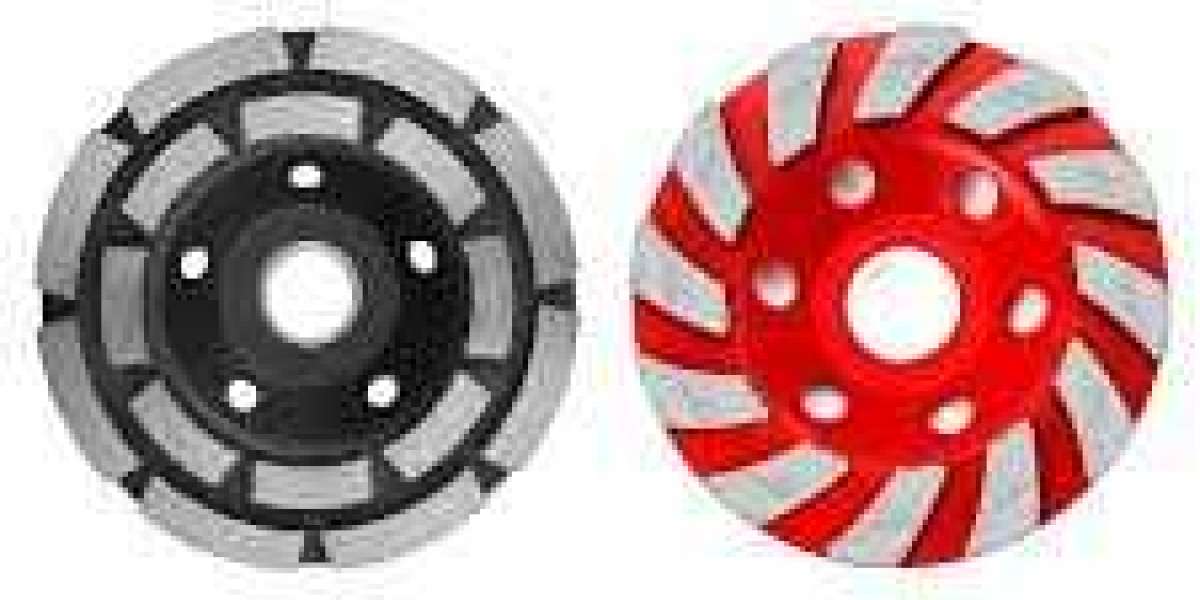

Grinder segments are abrasive tools designed to enhance the cutting and grinding capabilities of machines. Crafted with meticulous precision, these segments are often made from high-quality materials such as diamond or cubic boron nitride. Their diverse shapes and sizes cater to specific grinding needs, offering a customized approach to material removal.

One of the key advantages of grinder segments is their ability to maintain consistent performance over prolonged usage. Their durability ensures prolonged operational life, reducing the frequency of replacements and minimizing downtime. This not only enhances productivity but also proves cost-effective in the long run.

Whether it's in metalworking, construction, or woodworking, grinder segments play a crucial role in achieving the desired surface finish. Their adaptability to different materials and applications makes them indispensable for professionals seeking precision and reliability in their grinding operations.

In conclusion, grinder segments may be small in size, but their impact on industrial processes is undeniably significant. These abrasive powerhouses are the secret behind the impeccable surfaces and precise finishes we encounter in our daily lives, making them an essential component in the world of grinding technology.